Metal Fabrication: What things to Expect From Your Metal Fabricator

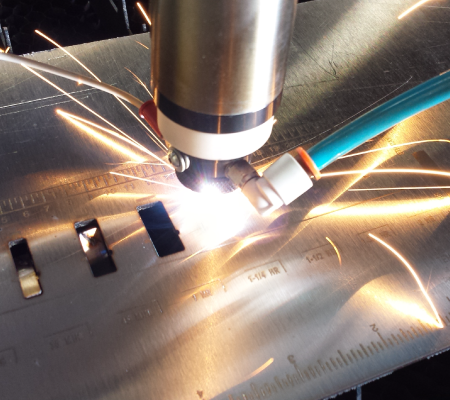

Metal fabrication may be the term used to spell it out the procedure of bending, cutting, and assembling metal structures from various metal parts and pieces. The procedure of cutting the metal during fabrication is normally done through sawing or shearing, laser cutting or punching. The process of bending is performed through press brakes. Press brakes use various dies to be able to achieve the different types of bends which are required by way of a project. Both cutting and bending of the metal during fabrication will be the first steps. Once each pieces of metal are cut and bent to their appropriate shapes and sizes, they are assembled together through welding.

Stamping is another process in metal fabrication that is used for large levels of the same part. Discover more here is creating a stamp, or mold that is found in a stamping machine to stamp the parts out of a bit of sheet metal. This technique is used for making a big quantity of the same part. It is expensive to build the mold, but once the mold is obtained, many parts can be made quickly thus decreasing the cost per part. Stamping is often used for items such as vents, panels, hinges, and much more.

While numerous kinds of metal are used in metal fabrication, steel is by far and away the most common. Steel can be an alloy of primarily iron with varying amounts of carbon added, generally 0.2% to 2.1%. Carbon may be the most typical alloying element because of it being the cheapest cost and adding desirable traits to the metal such as increased strength, malleability, and hardness depending upon the quantity of carbon added. While carbon steel is extremely useful and versatile, one problem with it is that it corrodes and rusts. If that is a concern for the project, then your item must be either coated or painted for protection, or instead can be made of stainless for corrosion resistance. An alloy of steel, chromium and nickel creates the most frequent type of stainless steel fabrication that is Type 304, or "surgical steel". The alloys described above just some of the vast selection of metals that are available for use. When planning a project which involves metal fabrication, one should be able to depend on their metal fabricator to recommend and acquire the best kind of metal for his or her purpose.

Metal fabrication can be an industry that is growing. There exists a wide variety of fabricators and it's important to select the company that will best serve your preferences. A good fabricator will be able to recommend the very best metal, have the ability to design assembling your project for manufacturing, and also have a capable manufacturing facility in order to provide you with the best product at the best price.